Fiberglass geogrids are referred to as fiberglass geogrids in our work. It is an excellent geosynthetic material for pavement reinforcement, old road reinforcement, roadbed reinforcement and soft soil foundation. Fiberglass geogrid has become an irreplaceable material in the treatment of reflective cracks in asphalt pavement.

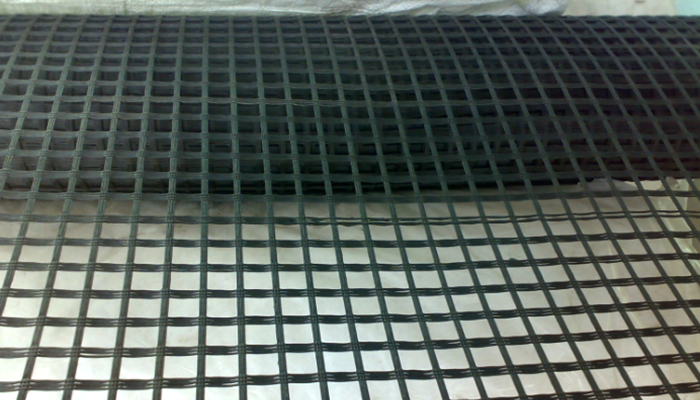

This product is a semi-rigid product made of high-strength alkali-free fiberglass through the advanced warp knitting process to make a mesh base material and surface coating. It has high tensile strength and low elongation in the warp and weft directions, and has excellent properties such as high temperature resistance, low cold resistance, aging resistance, corrosion resistance, etc. It is widely used in asphalt pavement, cement pavement and roadbed reinforcement and railway. Subgrade, dam slope protection, airport runway, sand control and other engineering projects.

Fiberglass geogrid is made of high-quality reinforced alkali-free fiberglass yarn, woven into base material by external advanced warp knitting machine, using warp knitting oriented structure, making full use of the strength of yarn in the fabric, improving its mechanical properties, making it have good High tensile strength, tear strength and creep resistance, and it is a flat network material coated with high-quality modified asphalt. It follows the principle of similar compatibility, focuses on its composite performance with asphalt mixture, and fully protects the glass fiber base material, which greatly improves the wear resistance and shear resistance of the base material, so that it can be used for pavement enhancement and resistance. The occurrence of road diseases such as cracks and ruts has ended the difficulty of strengthening the asphalt pavement.

Fiberglass geogrid product features:

The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long life and so on. Slope protection, road and bridge pavement enhancement treatment and other engineering fields can strengthen and reinforce the pavement, prevent pavement rutting fatigue cracks, hot-cold expansion cracks and reflection cracks below, and can disperse the bearing stress of the pavement, prolong the service life of the pavement, high Low tensile strength, low elongation, no long-term creep, good physical and chemical stability, good thermal stability, fatigue crack resistance, high temperature rutting resistance, low temperature shrinkage crack resistance, delay and reduction of reflection cracks.

Fiberglass geogrid product application:

1. The old asphalt concrete pavement is reinforced to strengthen the asphalt surface layer to prevent diseases.

2. The cement concrete pavement is converted into a composite pavement to suppress reflection cracks caused by plate shrinkage.

3. Road extension and improvement project to prevent cracks caused by the junction of new and old and uneven settlement.

4. Reinforcement treatment of soft soil foundation is conducive to the consolidation of soft soil water separation, effectively inhibits settlement, uniform stress distribution, and enhances the overall strength of the roadbed.

5. The semi-rigid base of the newly built road produces shrinkage cracks, and the reinforcement is reinforced to prevent the cracks of the road caused by the reflection of the base cracks.

Post time: Sep-14-2022