18 Years Factory Ground Cover Fabric - Non-woven Geotextiles For Isolate Construction Materials – Beihai

18 Years Factory Ground Cover Fabric - Non-woven Geotextiles For Isolate Construction Materials – Beihai Detail:

Product Introduction:

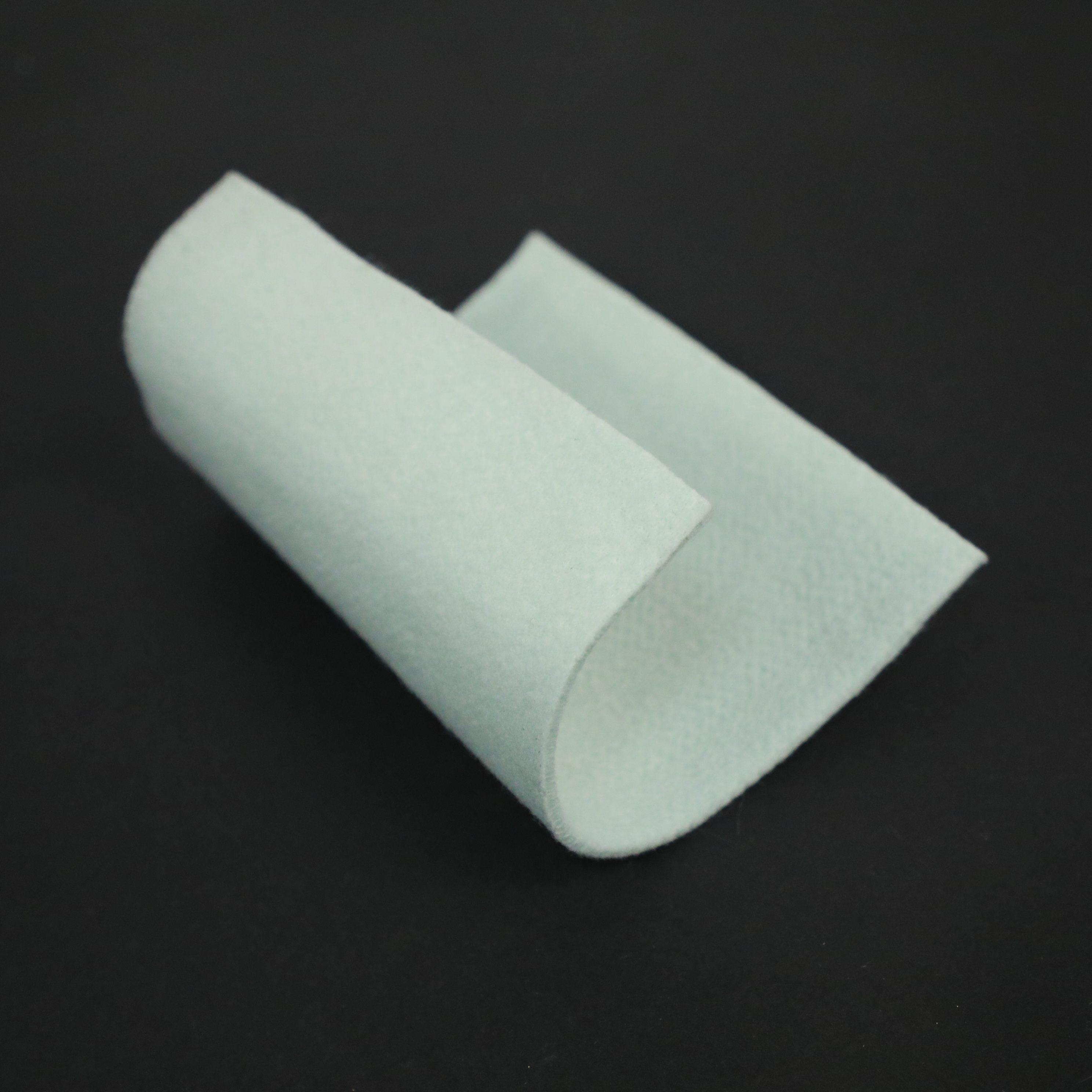

Non-woven Geotextiles (also known as permeable geotextiles, filter geotextiles, non-woven geotextiles), and divided into short fiber needled geotextiles and polyester filament geotextiles, gram weight in 100g-1200g, geotextiles is a nonwoven and industrial cloth. The permeable geosynthetics are made by the process of non-woven production equipment, such as loosening, carding, cluttering (short fibers interwoven together), netting (normalized entangling and fixation), and needling.

Product Features:

1. Non-woven Geotextile is used to isolate construction materials with different physical properties (particle size, distribution, consistency and density, etc.), such as soil and sand, sand and gravel, soil and concrete, etc

2. Filtration when water from the fine soil into the coarse soil, the use of geotextile good air permeability and water permeability, so that water through

3. Drainage It can form a drainage channel in the soil structure, the soil structure of the excess liquid and gas out

4. Reinforcement using geotextile to enhance the tensile strength and anti-deformation ability of soil, enhance the stability of building structure, to improve the quality of soil

Product Specification:

There are two kinds of Non-woven Geotextile:

1.PET Long Filament Geotextile

| PET Long Filament Geotextile Performance Parameter | ||||||||||

| Item | Technical specifications | |||||||||

| Breaking strength KN/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

| 1 | Longitudinal and transverse breaking strength KN/m≧ | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

| 2 | Longitudinal and transverse standard strength corresponds to elongation % | 40-80 | ||||||||

| 3 | CBR Bursting strength /KN≧ | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

| 4 | Longitudinal and transverse tearing strength/KN≧ | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.1 | 1.25 |

| 5 | Effective aperture O90(O95)/mm | 0.05-0.20 | ||||||||

| 6 | Vertical permeability coefficient cm/s | Kx(10-1~10-3),K=1.0-9.9 | ||||||||

| 7 | Thickness mm≧ | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

| 8 | Width deviation % | ±0.5 | ||||||||

| 9 | Mass deviation per unit area % | ±5 | ||||||||

| Specifications fracture strength, the actual specifications between the adjacent specifications in the table, according to the linear interpolation method to calculate the corresponding assessment indicators, beyond the scope of the table, the assessment indicators are determined by mutual agreement between supply and demand | ||||||||||

| When the actual breaking strength is lower than the standard strength, the elongation corresponding to the standard strength is not judged as conformity | ||||||||||

| Standard values by design or negotiation | ||||||||||

2.PP/PET Short Fiber Geotextile:

| PP/PET Short Fiber Geotextile Performance Parameter | ||||||||||

| Item | Technical specifications | |||||||||

| Breaking strength KN/m | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | |

| 1 | Longitudinal and transverse breaking strength KN/m≧ | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 |

| 2 | Longitudinal and transverse standard strength corresponds to elongation % | 20-100 | ||||||||

| 3 | CBR Bursting strength /KN≧ | 0.6 | 1.0 | 1.4 | 1.8 | 2.5 | 3.2 | 4.0 | 5.5 | 7.0 |

| 4 | Longitudinal and transverse tearing strength/KN≧ | 0.1 | 0.15 | 0.20 | 0.25 | 0.40 | 0.50 | 0.65 | 0.80 | 1.0 |

| 5 | Effective aperture O90(O95)/mm | 0.07-0.20 | ||||||||

| 6 | Vertical permeability coefficient cm/s | Kx(10-1~10-3),K=1.0-9.9 | ||||||||

| 7 | Thickness deviation rate % | ±10 | ||||||||

| 8 | Width deviation % | ±0.5 | ||||||||

| 9 | Mass deviation per unit area % | ±5 | ||||||||

| 10 | Acid and alkaline resistance (Power retention rate) %≧ | 80 | ||||||||

| 11 | Anti-oxidation performance (Power retention rate) %≧ | 80 | ||||||||

| 12 | UV resistant performance (Power retention rate) %≧ | 80 | ||||||||

Prodct Application:

Widely used in water conservancy, electric power, mines, roads and railways and other geotechnical engineering:

1.Filter material for soil separation;

2.Reservoir, mine beneficiation drainage materials, high-rise building foundation drainage materials;

3.River embankment, slope erosion materials;

4.Reinforcing materials for roadbed of railway, highway and airport runway, and reinforcing materials for road construction in swamp area;

5.Frost and frost insulation materials;

6.Asphalt road surface crack resistance material.

Video

Product detail pictures:

Related Product Guide:

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for 18 Years Factory Ground Cover Fabric - Non-woven Geotextiles For Isolate Construction Materials – Beihai , The product will supply to all over the world, such as: Cannes, Zambia, Brunei, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!