Hot Sale Manufacturer Provides EVA HDPE Smooth Geomembrane EVA Extrusion Geomembrane Fish Farm Membranes For Pool

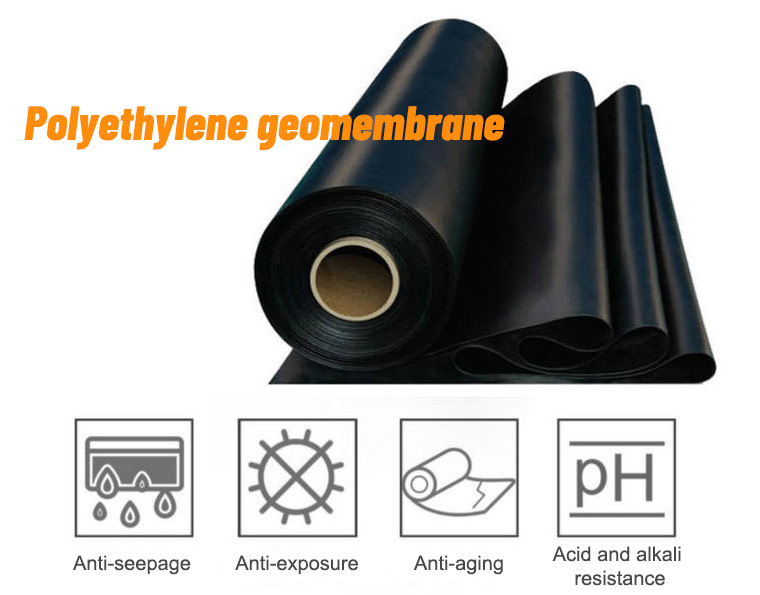

HDPE anti-seepage membrane is mainly divided into two categories: fish pond anti-seepage membrane and lotus pond anti-seepage membrane. High-quality polyethylene virgin resin is selected. The main components are 97.5% high-density polyethylene, about 2.5% carbon black, anti-aging Agents, antioxidants, ultraviolet absorbers, stabilizers and other auxiliary materials are made by the current world-class automatic anti-seepage film production equipment and three-layer co-extrusion technology. All products have reached the American standard, and the service life of buried underground is more than 50 years. It can meet the application requirements of environmental protection and sanitation, and widely used in fish pond anti-seepage projects, fish pond anti-seepage projects, lotus root planting, municipal engineering, gardens, landscapes, petrochemicals, mining, salt industry, agriculture, and aquaculture.

Features:

High tensile strength, low elongation, uniform longitudinal and lateral deformation, high tear strength, excellent wear resistance, and strong impermeability and water resistance.

Uses:

1. Environmental protection and sanitation (such as domestic waste landfills, sewage treatment, toxic and hazardous substances treatment plants, hazardous goods warehouses, industrial waste, construction and blasting waste, etc.)

2. Water conservancy (such as anti-seepage, plugging, reinforcement of dams of rivers, lakes and reservoirs, anti-seepage of canals, vertical core walls, slope protection, etc.)

3. Municipal engineering (subway, underground engineering of buildings and roof reservoirs, seepage prevention of roof gardens, lining of sewage pipes, etc.)

4. Gardens (artificial lakes, ponds, pond linings of golf courses, slope protection, etc.)

5. Petrochemical (chemical plant, oil refinery, oil storage tank anti-seepage of gas station, chemical reaction tank, lining of sedimentation tank, secondary lining, etc.)

6. Mining (washing tank, heap leaching tank, ash yard, dissolution tank, sedimentation tank, storage yard, bottom lining anti-seepage of tailings pond, etc.)

7. Lotus root planting (lotus root planting, anti-seepage of lotus pond, water storage pond, anti-seepage of irrigation system)

8. Aquaculture (lining of fish ponds, shrimp ponds, sea cucumber circle slope protection, etc.)

9. Salt industry (salt field crystallization pond, brine pond cover, salt film, salt pond plastic film)

Anti-seepage membrane construction plan:

Do not drag or pull the geomembrane during transportation to avoid being stabbed by sharp objects.

1. It should extend from the bottom to the high position, do not pull too tight, and leave a margin of 1.50% for local sinking and stretching. Taking into account the actual situation of the project, the slope is laid in the order from top to bottom;

2. The longitudinal joints of two adjacent sheets should not be on a horizontal line, and should be staggered by more than 1m;

3. The longitudinal joint should be more than 1.50m away from the dam foot and the bent foot, and should be set on the plane;

4. Slope first and then the bottom of the field;

5. When laying the slope, the direction of film expansion should be basically parallel to the slope line.

layout

1. Before laying geomembrane, the corresponding qualified acceptance certificate documents of civil engineering should be obtained.

2. Before the geomembrane is cut, its relevant dimensions should be accurately measured, and then cut according to the actual size. Generally, it is not suitable to cut according to the size shown in the figure. It should be numbered one by one and recorded in detail on a special form.

3. When laying geomembrane, it is necessary to strive for less welds, and on the premise of ensuring quality, try to save raw materials. At the same time, it is easy to guarantee the quality.

4. The lap width of the seam between the film and the film is generally not less than 10cm. Usually, the direction of the welding seam is parallel to the slope, that is, it is arranged along the slope direction.

5. Usually in corners and deformed areas, the length of the seam should be shortened as much as possible. Except for special requirements, on slopes with a slope greater than 1:6, within 1.5 meters from the top slope or the stress concentration area, try not to set welds.

6. During the laying of the geomembrane, artificial folds should be avoided. When the temperature is low, it should be tightened as much as possible and paved.

7. After the geomembrane is laid, walking on the membrane surface, moving tools, etc. should be minimized. Any objects that can cause harm to the impermeable membrane should not be placed on the membrane or carried on the membrane to avoid damage to the membrane. cause accidental damage.